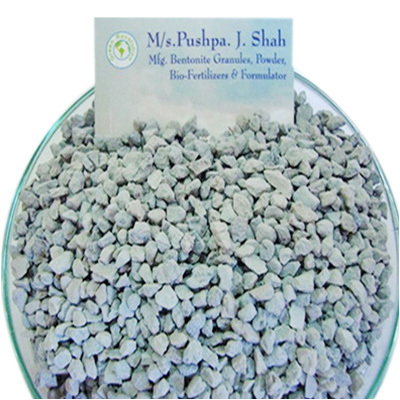

Raw Bentonite Granules

What is It: Raw Bentonite Granules are made from selected pure stone free Bentonite clay

Uses: They are widely used as carrier in formulation of pesticides, herbicides, fungicides, bio-pesticides, Plant growth promoter and Bio-fertilizers. Apart from filler, it also benefit as natural soil conditioner.

Proprieties: It is soft clay, it loosens the soil and allows air as well as other nutrients to reach the roots. If it is mixed with seed while sowing it soften the soil near the seed and help the new roots to grow. On coming in contact of water it immediately allow the formulated to release in soil. It is a low cost but natural friendly product.

- Size: 08-10 ASTM (2.36 MM to 2 MM)

- Oversize under size +/- 5%

- style="margin-bottom: 0.0001pt; line-height: 150%;">Formulation: Granular

- Liquid holding Capacity: Free flowing at 7 % mass by mass.

- Packing: Second hand HDPE bags.

- Bags weight: 35 kg approx

- It is Non hazardous and nature friendly filler

- PH: 7 (Neutral)

- Minimum order quantity: 10 MT

High Swelling Capacity and Water Absorption

These Bentonite Granules feature extraordinary expansion, swelling up to 10 times their original size. With an impressive water absorption capability of up to 600%, they are well-suited for applications demanding rapid liquid uptake and volumetric increase, such as soil conditioning and sealing in drilling operations.

Natural Composition and Structural Integrity

Sourced as natural, unrefined clay, these granules retain high sodium content and essential oxides (Al2O3, SiO2, Na2O, CaO), ensuring strength and non-caking consistency. This composition supports heavy-duty applications where pastes or slurries maintain stability and reliability across diverse environments.

Versatile Applications Across Key Industries

From foundry sand bonding and agricultural soil improvement to drilling mud formulation and construction sealing, these bentonite granules are engineered for versatility. Their granular, free-flowing appearance and stable physical form make them easy to handle and deploy across industries, both domestically and internationally.

FAQs of Raw Bentonite Granules:

Q: How should Raw Bentonite Granules be used in agricultural applications?

A: In agriculture, Raw Bentonite Granules are typically incorporated into soil to improve its water retention and aeration. Their high swelling and absorption properties help prevent water loss, making them ideal for dry or sandy soils.Q: What is the process for utilizing Bentonite Granules in drilling operations?

A: Bentonite Granules are added to drilling fluids where they swell and disperse, forming a viscous slurry. This helps lubricate drill bits, stabilize boreholes, and seal borewall pores, enhancing drilling efficiency and safety.Q: When is it most beneficial to apply Bentonite Granules in construction projects?

A: These granules are most effective when used during the initial construction phase for sealing foundations, underground structures, and ponds. Their excellent swelling ability ensures superior waterproofing and soil stabilization.Q: Where are Raw Bentonite Granules sourced and processed?

A: Our bentonite granules are sourced, manufactured, and processed in India, which is known for its high-quality bentonite deposits. They are handled and packaged for export, supply, and trade worldwide.Q: What are the benefits of using granules with high sodium content and structural integrity?

A: High sodium content enhances the swelling and binding properties of the granules, while strong structural integrity ensures they do not cake or break down during storage and usage. This combination delivers reliable performance across all major applications.Q: How does the packaging type help preserve the quality of Bentonite Granules?

A: HDPE and Jumbo Bags provide robust protection against moisture and contamination, maintaining the granules natural properties and free-flowing consistency during transportation and storage.Q: What sets these Bentonite Granules apart from refined alternatives?

A: Unlike refined varieties, these natural, unprocessed granules retain more minerals and water-absorbing capacity, offering enhanced swelling, durability, and cost-effectiveness for multiple industrial uses.Enquiry